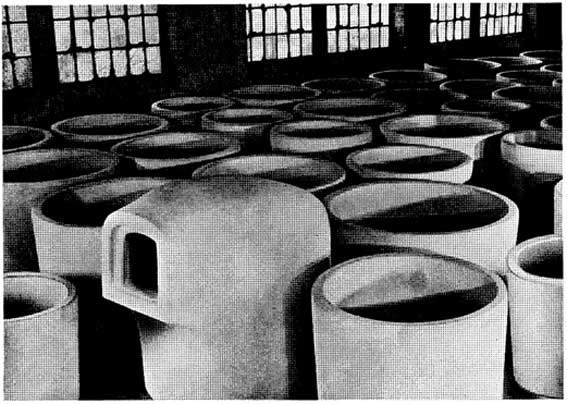

The making of the pot

Traditionally each glasswork made their own pots but it is a laborious and delicate process and by the late 1900's there was only one

ladle-making shop left, namely the one in Orrefors (

*). Everybody got their pots from Orrefors. But industrial memories of the pot-making

are commonplace; the pulverizing mills.

Such mills can be seen in most glass-work-municipalities like in the park "downtown" Hovmantorp.

The clay for the pots had to meet high demands and it was expensive, so the old pots were crushed and milled together with fresh minerals.

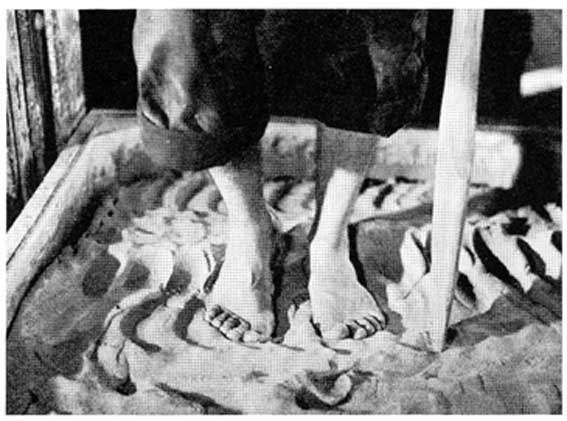

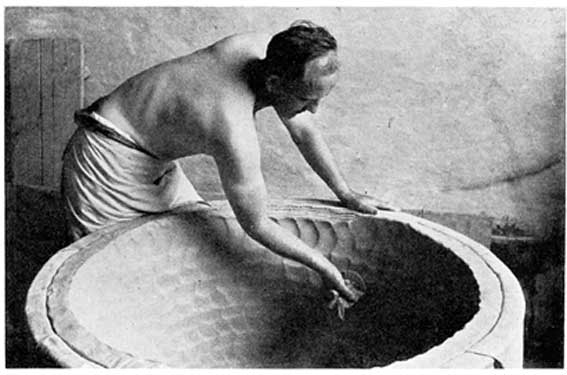

A binder was added to the mixture and the clay was then homogenized by tramping before the ladle was finally hand-made inside a wooden form.

The crushing mills, together with the cutting shops, were the glass-making processes that demanded mechanical power. So that explains why,

most often, glassworks are placed beside rivers and water-flows.

Making the clay, including the process of maturing, the shaping and the slow drying of the pot took about one year and only after that

could the pot be "tempered".

Tempering was done in separate tempering furnaces and the temperature in the furnace was successively raised from ambient to about

1300 degrees during a weeks' time. After this - one year after the manufacturing of the pot started - can the pot finally be used and

then it lasts only approximately two months...