Technological achievements

Basically, the same furnaces were used over millennia and so it was until the mid 1800's when three inventions were introduced:

-

The regenerative furnace developed by Siemens-Martin, introduced in Sweden about 1850. This construction opened for improved

control, radical fuel savings and also a much faster melting.

-

Another way (from regenerators) for energy management is to use recuperators. Axel Hermansen was inspired by a French design

and developed a recuperative furnace with an integrated gas generator. His construction, the Hermansen furnace, was completely

dominant in Småland from 1915 through the 1950's when oil- and gas-oil firing was introduced.

-

The third break-through was the continuous glass tank. This uses no pots at all, but raw material is fed at one end of a melting

basin and the molten glass is extracted continuously in the opposite end. But this type of furnace was far out of reach for the

small Swedish glassworks.

Even if driftwood, dry seaweed and fish rinsing's were enough to reach the temperatures needed for glass melting - and it is

obvious that logs from pine and spruce are just as good - does recuperative or regenerative air preheat give the opportunity

for higher temperatures. This was enough to more than double the production with the same amount of fuel. The alternative was to

maintain production but save fuel. Either alternative contributed to a strengthening of the economy in the sector and to

improve the competitiveness on the international glass market

Glass furnaces and their need of energy

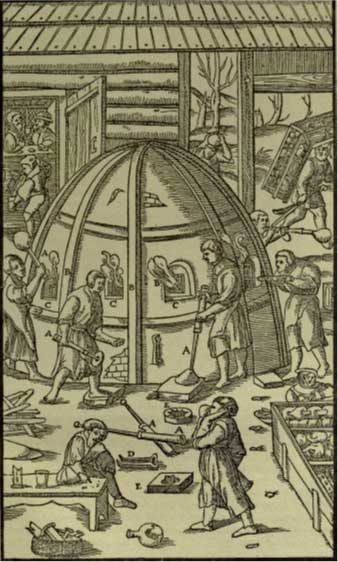

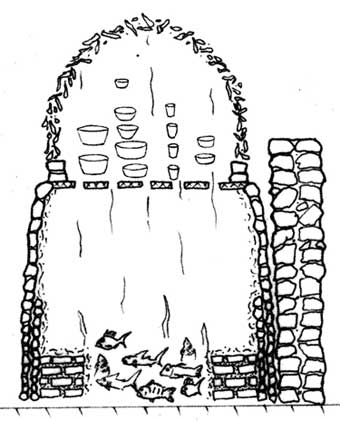

The simple ancient furnaces - like the one shown by Agricola or the one from Qualhat - were not too efficient. To obtain a quality

good enough for proper glass from sand, limestone and soda ash you have to set off a complex chemistry. This requires a temperature

around 12-1300

oC. Then will this very viscous glass have to be homogenised and that requires even higher temperatures,

around or above 1400

oC.

Then you allow the glass to cool to the more comfortable range 1100-1150 oC while working.

To make one kg of glass in a day and from virgin materials would theoretically take approximately 1 kWh. If the material is

re-cycled the demand is only about half.

-

For a comparison, the furnace construction from Qualhat probably demanded some 60-70 times as much or 60-70 kWh per kg glass produced.

-

The Swedish långugn, used until 1918, demanded about 20 times as much energy as the theoretical need.

-

The Hermansen design, with its recuperator, reduced the energy need to about 8 times the theoretical need.

-

Siemens' furnace, using a regenerator instead of a recuperator, was even better with an energy demand down at some

5-6 time the theoretical need.

-

Todays' small-scale glass manufacturers - like Bergdala - often use electrically heated furnaces and the electricity supply to the

furnace is about three times the theoretical need.

To provide the electricity, say 3 kWh per kg glass and day, you can choose either to input about 9 kWh nuclear fuel into a nuclear

power station or you can use about 6 kWh of energy in the blowing wind and buy the electricity (3 kWh) from a windmill or you can

use hydroelectricity from a hydroelectric power station and in that case the flowing water must provide about 3.3 kWh to the

turbine so that 3 kWh of electricity is supplied to the grid.

-

In the large scale you may find top modern glass tanks using so-called "cold-top" design. In those, the electricity input

is approaching the theoretical need so that only about 1.1 kWh of electricity is needed for 1 kg of glass per day. Such furnaces

are found only with the large flat-glass manufacturers or in the large-scale factories for container glass production.

No such furnaces can be found in Sweden.

A långugn fed with 10 m3 of wood-logs per day could thus produce about 150 to 200 kg of glass.

With the Hermansenugn those same 10 m3 would suffice for about - or more than - 400 kg of glass.

The Siemens regenerative furnace was more complicated but the same amount of wood would be enough for about 600 kg of glass.