When the press came to Sweden

As we have seen, the glass press made its entrance in the 1830ies: first Reijmyre, then Skönvik, Kosta...

All seemed ready for the glass pressing to triumph.

There were experiments with different types of presses, different materials for moulds. Strömberg

(Kostaglaset 1742-1916) writes about ceramic moulds, moulds made of brass and, later, iron.

But there were problems: at Kosta (Strömberg writes) one problem was that the moulds were not strong enough.

In the end the solution was that the smith took care of both moulds and the actual pressing.

It took more than ten years for Kosta to produce saleable press glass.

At Skönvik they had more problems. The owner, Carl Ramström, showed some items at an industrial conference in 1838, and got

lots of approval. The attending industrialists thought that "these examples are fully compatible with the imported goods,

both the clarity of the metal, the colours and the quality of the patterns".

Despite this, Skönvik did not succeed: the last year they pressed any glass was in 1842.

The accounts show that the total production for that year was 16 dishes, 180 bobèches (candle wax catchers) and 102 salt cellars.

That quantity should have been produced in one, possibly two days.

When the glassworks was closed in 1870, the press and the press moulds were still there, forgotten since nearly 30 years.

From around 1850-60 pressed glass became more common, and several glassworks bought presses.

The moulds were often imported, but eventually even the Swedes learnt to make press moulds. One of the still

remembered makers was named Johan Wilhelm Bergström from Stockholm. The reason he is remembered is that he marked his moulds

with IVB inside the mould: his signature shows on all items pressed in one of his moulds.

Here in Småland we prefer to remember Stenberg's foundry and mechanical workshop in Lindås outside Emmaboda.

The moulds from Stenberg often has a mark, but not where it shows on the glass.

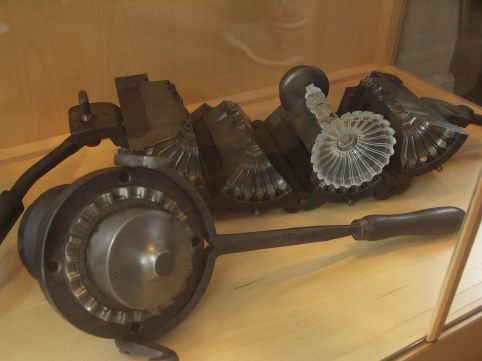

By this time the moulds had evolved, became more complex: open-and-shut moulds had two, three, four parts, to make it

possible to manufacture pieces with "strange" forms.

Below an example, probably made by Stenberg, open-and-shut mould in four parts, and the result: