Photo etching

The deep (line) etching was a fiddly process, with the wax coating and the mechanical scratching of the pattern. so in the 1940ies the photographer John Selbing of Orrefors started experiments in doing it in some other way.

In the book Bakom kameran och glasfasaden (ISBN 91-630-3350-X) printed in 1994, his wife Carola Selbing writes:

"Motivet, som skulle överföras på glaset, ritades först detaljerat med tusch och fotograferades av och av

negativet gjordes ett positiv, som kopierades direkt på den i förväg, med ljuskänsliga ämnen, preparerade glasytan.

Efter framkallning behandlades motivet med syra till en djupetsning."

My attempt at translation:

"

The motif, which was to be transferred to the glass, was first drawn in detail with indian ink, was photographed,

and from the negative was made a positive, which was copied directly to the glass, which in advance had been

prepared with light sensitive substances.

After development, the glass object was treated with acid to get a deep etching."

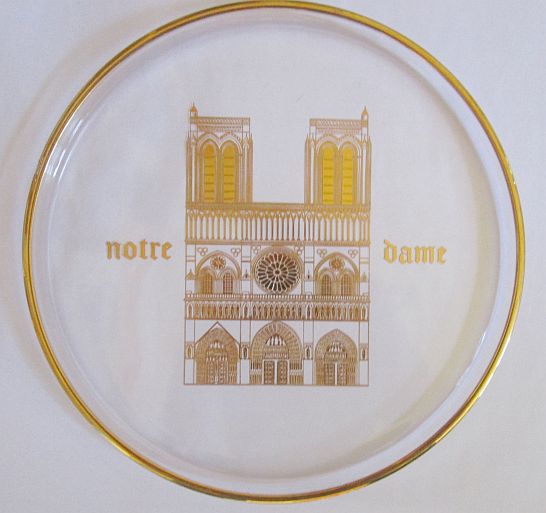

The method was further developed by adding gold into the deep-etched lines ans areas:

"Guldet, som var i en kolloidal lösning av nejlikolja, skulle målas eller sprutas på. Först försökte

John spruta guldet med en vanlig färgspruta men övergav denna metod, eftersom man blev tvungen att spruta hela

ytan och mycket guld försvann ut genom skorstenen."

My attempt at translation:

"

The gold, which was in a colloidal solution of carnation oil, was to be painted or sprayed on. First, John tried

spraying the gold with a regular paint spray, but abandoned this method, as it had to be sprayed all over the

surface and a lot of gold disappeared through the chimney."

Instead, John tried painting, but when the gold had dried, the gold on the raised surfaces should be taken off.

After several tries they found a way: the gold could be washed off with water and be re-used.

However, the problems did not end there:

"Uppmjukningstemperaturen för blyglas är 465 grader, men guldet måste brännas vid 550 grader för att det

skall fastna".

My attempt at translation:

"

The softening temperature for lead glass is 465 degrees, but the gold must be fired at 550 degrees to make it fast."

That problem, too, was solved, and a patent was granted on April 1952:

Svenskt patent 136565