The hot working

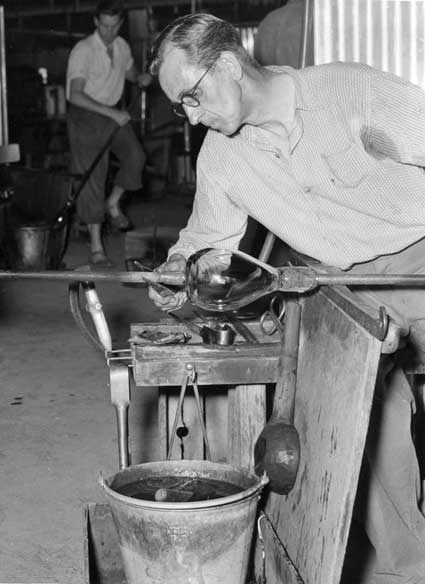

Manual glass blowing is touristic, spectacular and is one major reason that tourists come here at all.

At larger glassworks you will be able to see how a team, a production shop, of up to five persons or so,

each and every one being a specialist. The master ("gaffer")will be the one doing the most

complicated or sensitive operations.

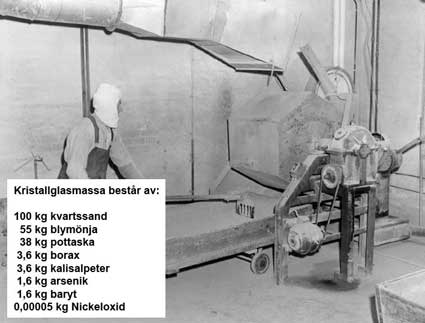

The temperature in the furnace will be lower than it was during smelting and refining, but a small part

of the additives will still be vaporized during this phase.

Thus a minute portion of glass will be lost in the form of gas, simply because it is so very hot. As

the gas cools down these substances will condense to form a microscopic dust that remains near the mill.

From the pipes, glass remnants are sheared off, and this, together with cutoffs and others fall into

the water in buckets and tubs and other collectors in the workshop.

Water is an amazing substance. Water can dissolve almost anything, iron and copper, gold and silver.

But some substances, such as glass, dissolve only very slowly. So if there is a very fine-grained dust

of glass on the ground around the glasswork, then will rain water slowly dissolve the glass, and then

the dangerous additives enter into the ground water. The smaller the dust particles - the faster the

dissolution.

Around each and every glasswork that has been in operation for more than a hundred years, there is

such a fine glass dust in the ground. Some originates from the handling of the pulverized batch,

some has come through the chimney and some has come out through doors and windows. Therefore, you

should be a little extra careful when staying on or playing around glassworks.

This applies at all glassworks and, indeed, it applies at all other process industries too!