Do you want to know more about sheet glass?

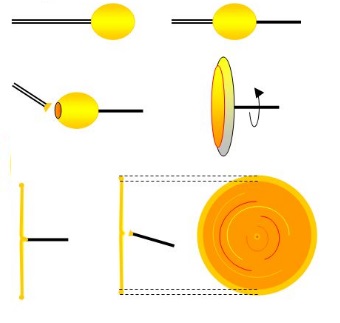

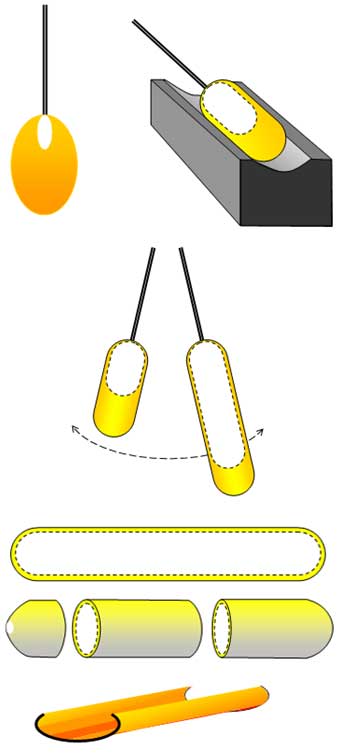

Sheet glass is much more common than most people think...

Most of the glass literature deals with art glass and other luxurious products.

But the economic backbone for the glass industry were the everyday products: mass produced eggcups, citrus presses,

table salt containers. These products, if mentioned at all, are often treated in a patronizing way.

The same applies to sheet glass. But sheet glass is by no means used only in windows. Sheet glass was a major product at

many Swedish glassworks for centuries - though not in Bergdala.

In 2012 our society published a book about sheet glass, its history, the methods etc. The book is called Planglas and can

be bought here in the museum, or from a couple of places on the 'web. However, it only exists in Swedish...