— — This is an outdated page, click here for the updated page — —

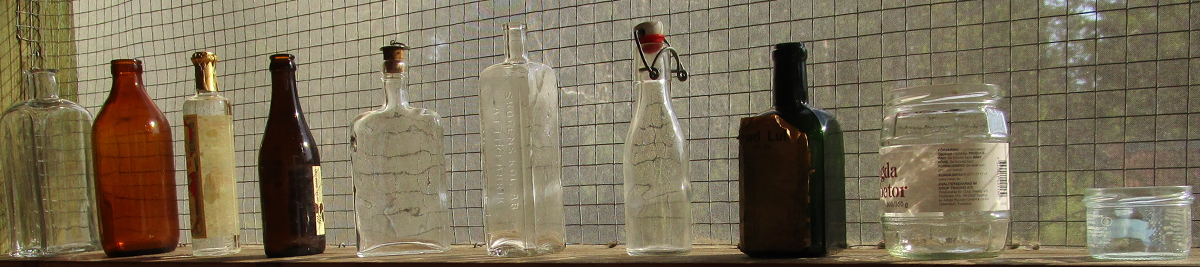

Production of bottles, jars and household items like that in a semi-automatic machine.

This machine was used here from (at least) sometime in the 1940ies up to the 1980ies.This machine was rigged with different moulds and tongs for the different types of bottles (or whatever) to be produced. For a blank surface, all tools had to be pre-heated before production started so they were put in the cooling furnace for some time. Then they had to be carried by hand and mounted.

- Covering the hole to the left end in the working table was placed a "primary mould". At the bottom of the mould was then placed a spacial tong with a blank holder to shape the mouth of the bottle. The neck and mouth of any bottle must be shaped to fit the sealing to be used and must also be reinforced by its design. The tong and its mould would be placed upside-down so that the would-be neck is pointing down and the future body of the bottle is pointing upwards.

-

At the far left end of the table is a lever attached to a bellows underneath the table. Moving the lever one way produces

a vacuum, moving it the other way blows air through the opening.

(Anecdote: a certain skill is needed to handle the bellows - each time this machine was to be used here in Bergdala, one of two specialists were called in: one from Åseda or one from Finspång.) - To the right, on the revolving table, were mounted two "final moulds". These were used alternately by turning the table halfway.

- To handle the hot glass a fork is mounted above the final mould.

Unfortunately, we only have one bottle-mould, which is why we have have placed it in the middle of the table.